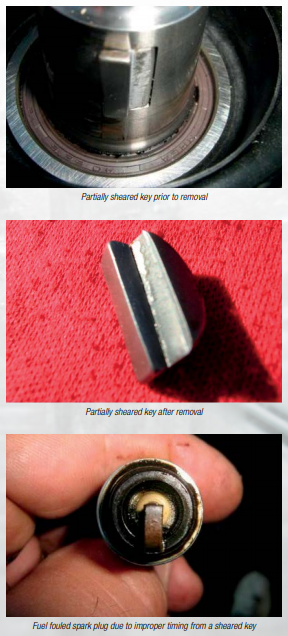

The flywheel key, also commonly called the

Woodruff key, is used as a positioning device on the

crankshaft to locate the flywheel (rotor) correctly.

If the flywheel is not correctly positioned, various

sensors (such as the crankshaft position sensor and

pulse coil sensor) that take timing information from

the flywheel will get incorrect information.

The flywheel key positions the flywheel, but it is

not designed to restrict flywheel movement on

the crankshaft. Such movement will shear the

key. Properly tightening the flywheel to the correct

torque, with the tapered area clean and dry,

ensures a tight fit to the taper on the flywheel and

crankshaft, binding the two into place.

If the flywheel is not torqued properly, several things

can happen in addition to the common problem of

a sheared flywheel key.

If it’s not tightened enough, the flywheel can come loose. But if the flywheel is tightened too tightly, such as with an air-impact gun,

the flywheel taper can be stretched, causing it to

become deformed and lose tension, also resulting in a

loosened flywheel.

Whatever the cause of flywheel loosening, extensive

and expensive damage will be caused. Depending

on the model, the flywheel could contact the stator,

pulser coil, crank position sensor, internal covers, and

wiring harness. Also, as the flywheel chatters, extreme

heat from friction could develop and fuse (weld) the

flywheel to the crankshaft.

Torque specifications exist for a reason. We need to

be sure to use the proper torque specified in each

engine’s service manual for all components, or we

may find ourselves with a situation like the ones

shown here.