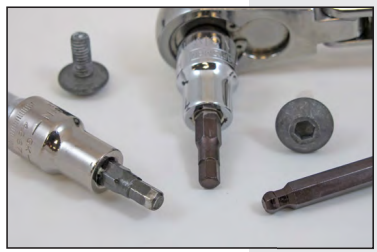

There are a few places on our motors where

hex drive fasteners are used, typically on

upper casing aprons and water intake

screens. A thread sealant is applied to the

apron fasteners to prevent salt and mineral

build up from making the screws impossible

to remove. While minimizing the effects of

salt, the sealant can make the fasteners

a little difficult to remove during service

operations. That’s particularly true if your

hex driver is nearing the end of its useful

life. The use of worn or incorrectly sized hex

drivers can damage the fastener, further

increasing the difficulty, as well as causing

resulting in lost time and efficiency.

Here are a couple of tips you may find

helpful:

• Replace worn hex drivers or grind off

the worn end before they are no

longer able to properly engage the

fastener socket causing slippage that

can end up damaging the fastener.

• Clean debris out of the hex that may

prevent full insertion of the driver into

the fastener.

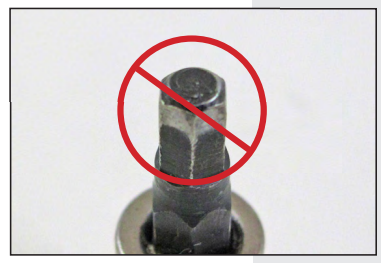

• Do not use ball-end drivers for

loosening these fasteners. Ball-end

drivers are great for many applications,

but they do not have the contact area

necessary to remove tight fasteners.

• When reinstalling fasteners, clean the

threads and apply a low-strength thread

sealant such as Loctite® 572™,

Loctite Quickstix® 561(p/n ACC-

QKSTK-56-10) or, in a pinch, a good

gasket sealer.