The Service manual provides the correct procedure for testing the Power Trim & Tilt

(PTT) relay, but the procedure can be a little vague. In this article we will provide more

detail about operation and testing.

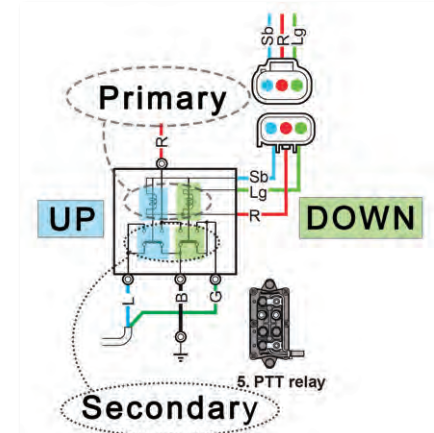

Relays are an electromechanical device commonly used to allow a circuit with a small

amount of current flow to control the function of another electrical circuit, normally one

that conducts a much higher current. The controlling side of the relay is referred to as

the “primary” while the side being controlled is referred to as the “secondary.” The PTT

relay’s primary circuit is controlled by the PTT switch or the Electronic Control Module

(ECM) on Digital Electronic Control (DEC) models. The secondary circuit is used to

control the PTT motor. Inside the PTT relay there are actually two relays combined into a

common housing. Both of the secondary contacts connect the two PTT motor wires to

ground when the relay is not activated.

When current is allowed to flow through the primary winding, it creates a magnetic field.

This magnetic field will “pull” the contacts of the secondary side closed, completing the

secondary circuit. Once the secondary circuit is completed, it will supply power to the

PTT motor while the other relay will provide the ground path.

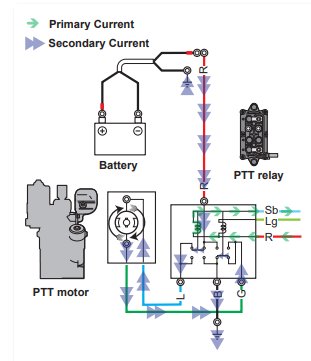

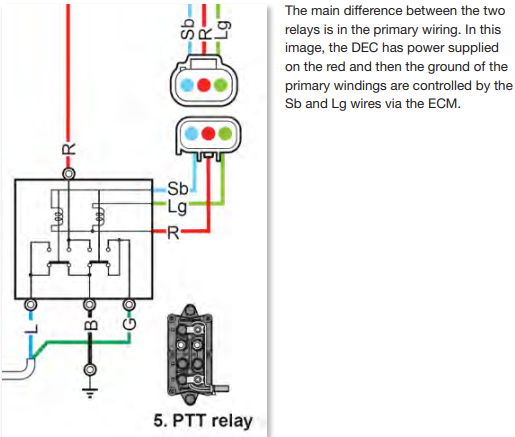

The diagram above shows the current flow when the UP (Sb wire) is grounded through

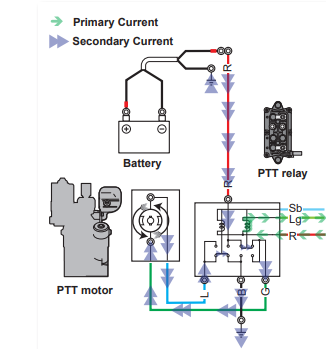

the ECM. The image below shows the current flow when the motor is being trimmed

down. The ECM will ground the Lg wire; this will activate the down section of the relay

and the PTT will spin in the opposite direction.

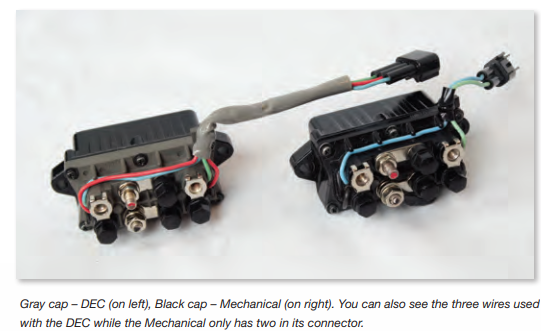

There are two different types of PTT relays in common usage. One is used with

mechanical systems, identified with a black cap. The other is used for DEC controls and

has a gray cap. In the mechanical system, the primary circuit is controlled by the PTT

switch. With the DEC systems, the ECM monitors the PTT switch and the ECM controls

the ground for the relay. The testing procedure only varies a little.

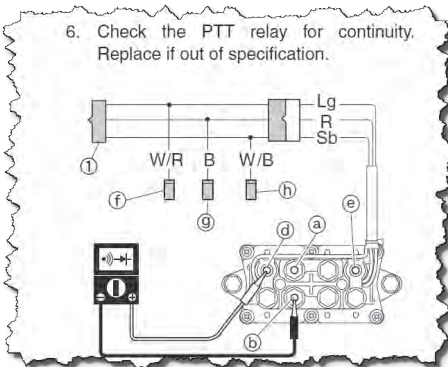

The Service Manual provides the correct test positions but states, “Check for continuity.

Replace the PTT relay if out of specification.” Continuity is defined as “uninterrupted

connection, succession, or union” by Merriam-Webster® and no other specification is

provided. Use these specifications as guidelines for both the DEC and the mechanical

versions: The primary side of the relay should have between 3 – 6 ohms of resistance

and the secondary should have less than 1 ohm.