Caring for the electrical system is a crucial part of the boating maintenance schedule and the battery is at the heart of this system. Here are some things to keep in mind and tips you can pass along to your customers to help keep them from having hassles on the water.

It’s usually pretty easy to distinguish between a serviceable and a maintenance-free battery. Those that have removable vent caps are serviceable and those that don’t are not. However, sometimes battery manufacturers hide the vent caps below the stickers they place on the top of the batteries. If you see a sticker with a perforation line running through it, tear it off to access the removable vent caps. This will alert both you and the owner to periodically check the fluid levels inside. If you are uncertain, check with the battery manufacturer to confirm if your battery is serviceable.

Check these levels at least every two months and more frequently in hotter climates. When checking the fluid level, the battery should be fully charged as the fluid level will be highest at full charge. Make sure to not overfill the cells to prevent electrolyte from leaking out as it expands with heat. Use distilled water when topping off the cells as tap water contains minerals and chemicals that will shorten the life of the battery.

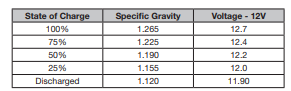

If you are testing a battery with a voltmeter, a fully charged “wet cell” battery should have a minimum reading of 12.7 volts. An AGM or GelCell will be slightly higher at 12.8-12.9 volts. A completely discharged battery will register below 12v and anything below 11v usually indicates a dead cell and therefore a bad battery.

When it comes to storing a battery in the off season, there are several things to remember. First, the battery should be fully charged and the fluid topped off. Second, ideally both cables should be removed from the battery terminals and it should be kept where it is dry and the temperatures will be between 40 and 70 degrees. These conditions will minimize the rate of self-discharge to about 5% discharge per month.

At this rate, it will take 5-6 months for the battery to drop below a 75% charge or a specific gravity of 1.225. This is important because it is at this point where sulfation begins. Sulfation hardens the battery plates, which leads to the battery’s inability to hold a charge. Almost 1/3 of all batteries today fail within 2 years and the number one cause of failure is sulfation.

Some common causes of sulfation are over or undercharging, usually the result of using a cheap or older charger; temperatures below 32º or over 100º, low electrolyte levels and parasitic drains. However, if caught early enough sulfation can be reversed using a smart charger. Another cause of sulfation is corrosion. If the cable connections to the terminals become corroded it hinders the charging process.

Lastly, vibration causes premature failure. Proper installation plays an important role in extending the life expectancy of a battery. A battery should be secured so that it won’t budge when pushing or pulling on it.