F150 History

The Yamaha F150 (F150TXR, TLR, XA, LA, XB and LB) is a solid reliable engine. There are well documented cases of 8000 plus hours in well maintained commercial applications. ( Charleston Water Taxi Article ) The F150’s are still being produced today (2004-2020) in more or less the same configuration. 16 years is a long time for an outboard engine model lifespan. The reason for this is simple, it’s a great engine.

F150 Balancer Information

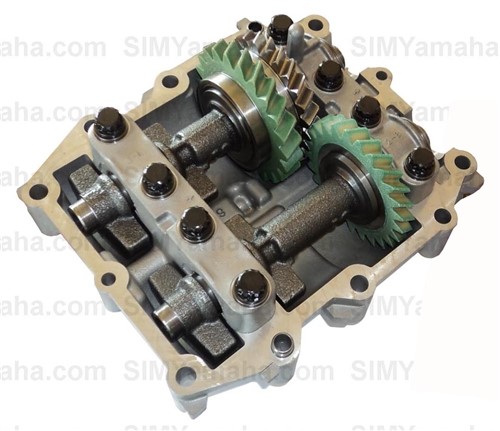

Yamaha uses a crankshaft gear-driven, counter-balancer in the F150 engine. This part is used to help the engine run smoother with less vibration. Since the F150’s inception in 2004, there have been 5 balancer design changes (we’ll call them generations) for the balancer. The point of this article isn’t to go through those actual changes, but to help you to tell what balancer you may have, so you can decide whether it needs to be changed to the latest/newest generation.

According to the Yamaha dealer number parts list, below is a part number list of what generation balancer was used on what model year engines. The third section of digits would signify what generation balancer your motor has. The -00 balancer would be the 1st and the -04 would be the latest.

| Yamaha Balancer Part Number | Engine Production Date | Generation |

| 63P-11500-00-00 | All C (2004) and D (2005) models | 1st Gen |

| 63P-11500-01-00 | Engine production dates of April 2005 thru March 2006 | 2nd Gen |

| 63P-11500-02-00 | Engine production dates of April 2006 thru March 2009 | 3rd Gen |

| 63P-11500-03-00 | Engine production dates of April 2009 thru January 2012 through 63P-1122573 | 4th Gen |

| 63P-11500-04-00 | Engine production dates of Jan 2012 starting with 63P-1122574 thru present time | 5th Gen |

Should I replace my F150 balancer?

It is highly recommended if you have a F150 with the original, never replaced balancer installed between the -00 and -02 balancer years (see above list), replace it with the latest -04 part number balancer part: https://www.simyamaha.com/BALANCER_ASSEMBLY_p/63p-11500-04-00.htm.

If you have a -03 balancer, still consider changing it. We don’t hear of or see as many -03 failures, but we have not seen or heard of any -04 failures to date. Yamaha changed the part from -03 to the -04 for some reason, so it would be wise to change it.

Regardless of year, if you have ever run hard aground you should replace the balancer. The balancer spins at twice the engine rpm and since it’s a directly connected part to the prop shaft, if you have a sudden engine stop from grounding, the green gears in the picture can be damaged. For example, if you are running at 5000 rpms, the balancer is spinning at 10,000 rpms. There has to be a significant amount of force applied to that assembly if it abruptly stops spinning from 10,000 rpms to 0 rpms.

How do I tell for sure what F150 balancer I have?

It’s very hard just by looking at the balancer parts themselves to tell which generation balancer you have. There was an oiling tower added with the -03 and -04 balancer. Another indication is Yamaha uses a cast-in date code on the front of the balancer. Below is a picture of what a date code looks like. There are 2 rows of digits with a line between them. The 5 in the 5D signifies the year (2005 or 2015) and the D signifies the month (D is April).

The second two-digit line is the day of the month the part was cast. It would be nice if Yamaha used a 2-digit code in the year line, because that would take a lot of the assumption out of it.

We had a customer that is in the casting business bring this to our attention, and over a couple of years of checking and testing these codes with new and used balancers, we have found this code interpretation to be accurate. As time goes on, it might be harder to use this assumption because Yamaha doesn’t use a 2-digit code for model years. What that means is the single year digit is repeated (i.e., 7 for 2007 and also 7 for 2017). So if you have a 2004 engine with a year code of 4 and it’s an engine you have owned since new and know the balancer has never been changed, you can assume its an original balancer from 2004 and therefore it should be changed.

But let’s say it’s a new engine to you (but it’s a used engine with no balancer service history) in the same scenario. How do you determine if it’s been changed and that year code doesn’t mean 2014? Good question! First thing I would look for is the red gel sealant you use when installing a new balancer. On original balancer installs from Yamaha, you typically don’t see that red gel seal oozing out between the balancer base where it meets the powerhead. When they are replaced in the field, you typically see that red gel sealant, sometimes significantly. Also look at the outside of the part. On a 2004 engine used in saltwater, that aluminum might have some minor corrosion on it from the years of service. If it looks like a new part and has red gel seal, chances are it is a newer part.

Another example – If you have a 2008 model year engine and you see a “3” on the year code line, you can assume that balancer was replaced with a 2013 production year balancer since a new 2008 engine would not have a 2003 or 2013 production year casting (unless it was replaced). In this case, you would have the -04 latest generation balancer.

Here are the year codes:

3 = 2003

4 = 2004

5 = 2005

6 = 2006

7 = 2007

8 = 2008

9 = 2009

0 = 2010

1 = 2011

2 = 2012

3 = 2013

4 = 2014

5 = 2015

6 = 2016

7 = 2017

And the month letter code:

A = January

B = February

C = March

D = April

E = May

F = June

G = July

H = August

J = September

K = October

L = November

M = December

Another way to determine if the balancer should be replaced is to listen to it while the engine is running. The below video was of a F150 we replaced a few years ago. The engine had about 1000 hours on it, mostly at idle speed (from fishing). Note the balancer noise – the pitch changes with rpm fluctuation. Once replaced, the balancer noise went away.

So what happens if I don’t replace my Yamaha F150 balancer and it fails?

It is hard to say for sure. In some cases, nothing happened. An oil pressure alarm went off, the customer would shut the engine off and discontinue use, then flushed the engine, replaced the balancer, engine oil and filter, and went on their way.

However, there have been instances where the cam shaft bearings have failed from the lack of lubrication. Unfortunately in other cases, this destroyed an engine. What happens when those gears fail is the debris gets into the engine oil, travels into the oil pan, and clogs the oil pump pickup screen. The engine oil pump then runs out of oil and the low oil pressure alarm goes off, causing the engine to go into rpm reduction mode. While damage at idle speeds in this event may be minimal, if it happens at higher rpms the damage could be irreparable.

So my balancer failed, now what should I do?

The balancer should be removed and inspected for the extent of failure. Depending on what we found there, we would recommend powerhead removal to gain access to the oil pump, oil pan and oil pickup tube, and screen, for cleaning or replacing. Also, we would remove the valve cover and inspect for damage to the camshafts and bearings. After installing a new balancer and new engine oil and filter, we would then test run the engine and monitor oil pressure. If those readings looked good and we hear no mechanical noise, we would change the oil and filter again, and disassemble the second oil filter to check for debris. Then we’d take the boat out for a sea trial, monitoring oil pressure and listening for noise. If it has good oil pressure and no mechanical noise, it should be OK.

These comments and suggestions are from SIM Yamaha and do not reflect, nor are they intended to represent, any position from Yamaha Motor Corp USA. SIM Yamaha freely offers this advice based on our years of experience selling Yamaha outboard engines, replacement parts and servicing Yamaha outboards. Our goal is to give you the information you need to properly maintain your Yamaha outboard engine.