Most people are familiar with the use of potentiometers even if they don’t know them by name. They are a simple form

of a voltage divider that can be used in a circuit to send a varying voltage signal that is a fraction of the input voltage.

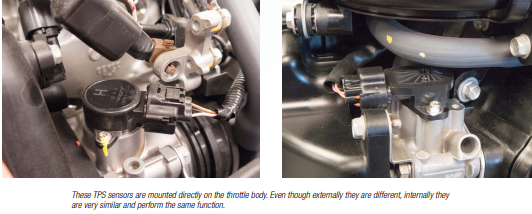

The throttle position sensor (TPS) is one of the most common uses of a potentiometer on an outboard motor. They are

also used as volume knobs on stereos, fluid level sensors in tanks, and other applications where a change either in

angle or in distance needs to be monitored.

In reality, potentiometer operation is simple; inside a sensor there is an exposed wire with fixed resistance, which is

called a trace, that is connected to the source voltage and ground terminals. The third connection is normally referred

to as the “output” or “signal.” It is attached to a wiper, a moveable pad, which touches the exposed portion of the

resistive wire. The wiper will move based on the changes from a knob or another device, such as a change in the

throttle plate angle in a TPS.

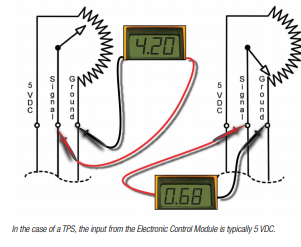

Voltage is lost when voltage pushes current though a resistance. Depending on where the wiper is touching the trace, the voltage level available on the

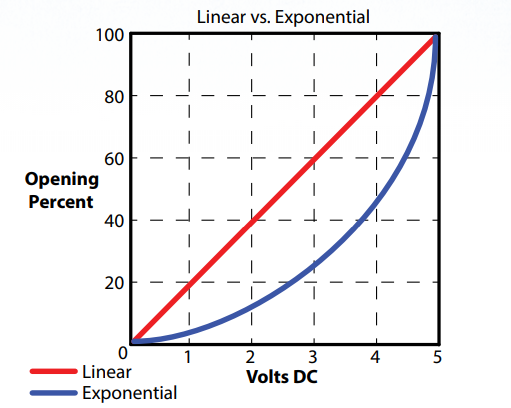

output pin will be a percentage of the overall voltage. Potentiometers can be designed to have linear or exponential

outputs. With a linear potentiometer, the change in voltage will vary proportionally. For example, if a linear potentiometer

with a source voltage of 5 VDC has the wiper exactly halfway, the voltage available on the output terminal will be 2.5

VDC. If the wiper is moved closer to the source voltage side, the output terminal voltage will increase. If the wiper is

moved towards the ground side, the output terminal voltage will decrease.

Not all potentiometers are linear, though. An exponential potentiometer can be designed so that its output is not directly

proportional. This can be advantageous when applied to some user interfaces and is common with audio controls.

Potentiometers can suffer from wear and contamination. The wiper can slowly wear on the trace to the point that it may

lose contact and not produce an output voltage. Also, worn seals can cause corrosion issues that affect output. In the

case of the TPS, these issues can have a drastic effect on the running condition of a motor.

Before replacing a potentiometer you think has failed, be sure to check for the correct input voltage and a good ground.

This includes looking for poor connections and voltage drop on either of those wires. Do the same on the signal wire,

making sure to use the appropriate test harness to avoid accidentally damaging the harness.