Let’s look at some common complaints for the Precision Blend System or PBS.

“… the oil pump does not run … system will not transfer oil to the engine oil tank ….”

There are a couple of checks /possibilities here:

• The first check should be a visual one. Look for corroded or damaged wires and connections; Remote Oil

Tanks are often mounted in areas that are exposed to more moisture.

• Operate the override switch mounted near the Engine Oil Tank to see if the pump will run. If it does, either the

engine tank’s float assembly is inoperative or the oil-controller (located inside the ECU) is faulty. To check the

float assembly, disconnect the wiring plug and ground out the blue-green wire on the wiring harness side. If

the pump and wiring are in good condition, the pump should stay on. Grounding the blue-white wire will turn

the pump off.

• Verify that the pump does operate by

disconnecting the harness going to the

Remote Oil Tank and applying straight 12

volts across the two leads (brown lead

positive / blue lead negative) using some

jumpers.

• If the pump does run based on the above checks, check the engine oil tank sensor with an ohmmeter. The

procedure is in the service manual.

– CAREFULLY remove the sending unit from the Engine Oil Tank. There is a felt type washer on the bottom of

the sending unit. If it stays in the oil tank, it could clog the outlet to the oil pump resulting in no oil getting to

the engine.

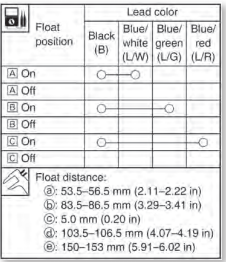

– SW2 is the switch that sends the signal to the ECU to turn the transfer pump ON. Connect an ohmmeter

across the blue/green–black leads in the connector and move the float over the area of SW2. The meter

should indicate continuity when the switch CLOSES and O.L. when it is OPEN.

Test all 3 switches in this manner using the color

code chart to the right.

SW1 sends the signal to the ECU to turn the

pump OFF.

SW3 sends the signal to turn the warning horn

ON and put the engine in the Reduced RPM

Mode.

If all of the tests listed above check out

(pumps runs, switches check OK, filter is good) the problem could in the ECU.

“… the pump runs but oil will not transfer ….”

• Check the filter on the outlet side of the Remote Oil

Tank – this is a common problem. Lots of things can

find their way into the oil tank – especially the seals

found on the tops of the oil bottles! It is recommended

that this filter be part of any routine maintenance

program.

• Is the oil line between the Remote Oil Tank and the

Main Engine Oil Tank kinked, pinched, or twisted? This

could be possible if the tank had ever been removed

for service or a re-power situation and was clamped

down on the hose.

Other symptoms to watch for:

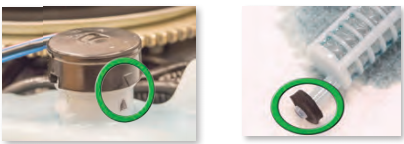

Overfilling: An overflowing Main Engine Oil Tank can result from removing the sensor assembly from the Engine Oil

Tank, and incorrectly re-installing it. There are arrow marks on the cap and filter and should be aligned (shown below

on the left). There is an offset that fits into the bottom oil outlet going to the metering pump. If misaligned, it could

bind the float and not allow it to stop the transfer pump from running. The foam washer, highlighted in the image on

the right, must be in place. If not, it could be trapped in the outlet going to the metering pump restricting oil flow.

NOTE: Always add oil to the Remote

Oil Tank! Never remove the Engine Oil

Tank sensor to add oil!

Always refer to the appropriate service manual for correct information on wiring, specifications, and assembly

procedures.

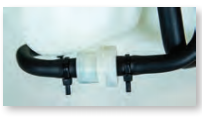

Leaking when tilted: While the outboard is tilted, a leaking rubber cap on the Main Engine Oil Tank can result from

improper assembly or from being out of place. A plastic tie-wrap around the rubber lip often cures the leak; if not,

replace the sensor.

Can I bypass PBS?

Here’s one I’m sure you have heard:

“I want to bypass the PBS system and pre-mix my fuel and oil in the gas tank because I don’t trust it….”

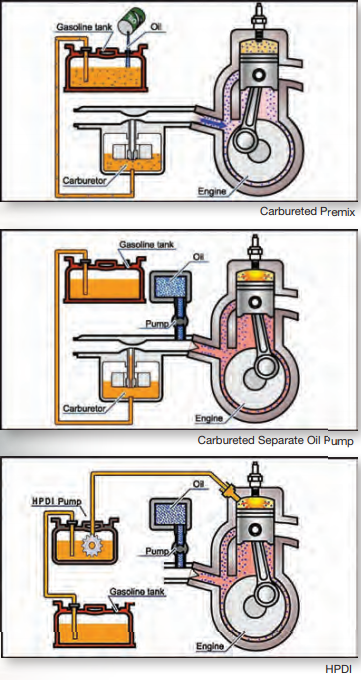

Let’s address the obvious first: you cannot bypass the oiling system and run strictly pre-mix on an HPDI! Why?

Think about what the letters HPDI stand for: High Pressure DIRECT INJECTED. Fuel is injected directly into the

combustion chamber; oil is injected into the intake manifold to lubricate the bottom end. With the PBS system

disabled there would not be any lubrication passing through the bottom end as it does on a carbureted engine

when the oil is mixed with the fuel (or, like the old OX66 engines, oil injected into the vapor separator)!

Pictured above are the oil lines on an HPDI connected to the intake manifold behind the throttle bodies. These

throttle bodies only flow air which carries the oil through the power head.

This is why pre-mixing for break-in is not required on HPDI. Some that are pre-mixing as a “safeguard” are

wasting oil and could cause engine damage by causing the engine to run too lean, because the extra oil is displacing

some of the fuel that should have been injected.

Secondly, why would you want to bypass it in the first place? This system has proven to be so reliable that Yamaha

has used it for decades with very few changes.

If you are having issues with the PBS system, odds are it is an easy fix, or maybe they do not fully

understand how it operates.

Notice in each case the oil is added to the bottom end of the

engine to provide lubrication to crankshaft, connecting rod,

and piston and cylinder.