Many Yamaha motors use metal gaskets between

major components, such as cylinder heads and the

crankcase, as well as the crankcase-to-upper-casing

exhaust guide. Most of these metal gaskets use

factory-applied surface coatings and raised ribs to

seal between components. There is no need to apply

additional sealant when reassembling components.

In fact, when additional sealant is applied, it typically

winds up in the oil pan, eventually finding its way

to the oil pick up screen and restricting oil flow. We

all know what happens after the screen becomes

clogged.

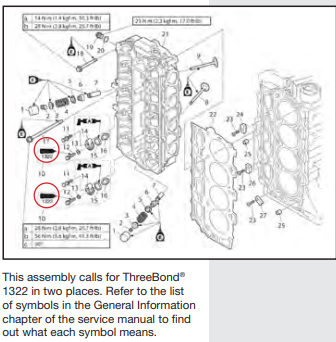

If in doubt about where to use sealants when

assembling components, always refer to the

applicable Service Manual. When sealants are

required at specific locations, there will be a tube

icon with the sealant number as shown in the

adjacent F150 cylinder head assembly drawing.

Notice there is no sealant specified for the cylinder

head gasket.

When assembling components that use metal

gaskets, it is important that neither gasket surfaces

nor component mating surfaces have scratches. Also, pay particular

attention to sealing ribs that may have been crushed

or dinged due to improper handling