For some of us, unfortunately, the boating season is limited to the nicer weather that comes with the summer months. In just a few months it will be time to start thinking about putting boats away for those of us in the northern part of the US. There are still some seasonal maintenance items that should be taken care of as the temperature begins to change to help ensure that the motor and boat continue to operate reliably.

Fuel: In many areas of the nation, fuel supplies switch from summer to winter blends. This is for environmental reasons and so that motor will be

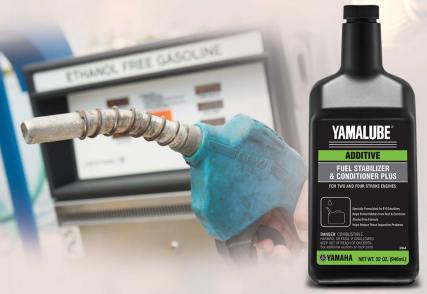

able to start easily with colder temperatures. Check to see if your area is an area that does this. If you try to run a motor once the weather gets cold and it still has summer gas in the tank, you can experience starting issues and other negative running conditions. If you use your boat less frequently, if at all, during the winter months, make sure to use Yamalube Fuel Stabilizer & Conditioner Plus to help ensure that fuel in the system doesn’t foul and cause problems the next time you go out.

Oil: Please change the oil before putting the boat away for the season or even as the usage begins to decrease with cooler weather. Combustion byproducts can accumulate in the oil and contribute

to degradation of the oil’s additive packages, reducing their effectiveness, especially those blended into oil to help prevent internal component corrosion. At the same time, cold-water temps make it harder for water condensation that has accumulated inside the motor to be burned off – the operating temperature may not get high enough for the water to turn to vapor and be eliminated. Additionally, colder winter temperature can add to longer warm-up times with a rich fuel/air mixture, possibly contributing to oil dilution that directly affects the oil’s ability to lubricate critical components. Getting fresh oil into the motor will help to ensure that contaminants like these won’t have a chance to causes problems as the boat spends less time in operation.

Batteries: A dead battery? What a drag. Fortunately, this problem can be a

thing of the past with a small amount of effort. Make sure that you have an understanding of proper battery maintenance, such as checking the electrolyte level on serviceable batteries, cleaning connections, and treating them with anti-corrosion spray. And most importantly, of course, using the right kind of battery charger when the boat is going to be sitting for a long time. A discharged battery is much more susceptible to sulfation and internal damage during cold temperatures.

Details: Boats are a significant investment and making sure that they look their best helps them retain their value. A good wash and wax can help keep surfaces of the boat and the motor looking new. This helps to remove surface contamination that can damage the boat’s gel coat or paints clear coat when left for extended periods of time. Also, silicone spray applied to rubber components will help keep them soft and reduce weathering so their lifespan isn’t inadvertently shortened.